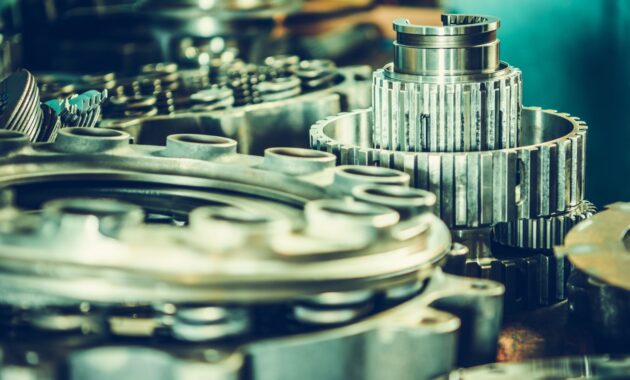

Machines are the workhorses of modern industries. From manufacturing plants to construction sites, these mechanical marvels power our world. But even the most robust machines can experience wear and tear, requiring replacement parts to maintain peak performance. If you’re a machine maven, you understand the importance of securing top-notch gear parts to keep your machinery running smoothly. This article will explore six essential tricks to help you source high-quality gear parts, ensuring your machines operate efficiently and reliably.

Forge Relationships with Reputable Suppliers

Building relationships with reputable suppliers is crucial for consistently sourcing high-quality gear parts. Look for suppliers with a history of providing genuine and reliable components. Reputable suppliers often offer a wide range of parts and have the expertise to assist you in finding the right gear for your machine. Explore the internet, where you may come across everpads.com, a reliable online platform known for its extensive selection of top-quality gear parts and a reputation for customer satisfaction. These reputable suppliers are often willing to go the extra mile to help you find the specific gear parts you need, whether they are for routine maintenance or addressing unexpected issues.

Trade shows and industry events are also excellent opportunities to network with suppliers and learn about the latest developments in machine technology and parts. Engaging with industry professionals can help you establish connections with trusted suppliers and stay updated on emerging trends. Additionally, these events often feature seminars and workshops where you can gain valuable insights into cutting-edge technologies, innovative gear solutions, and best practices for maintaining and optimizing your machines.

Know Your Machine’s Specs

To find the right gear parts, you must deeply understand your machine’s specifications. Familiarize yourself with its make, model, and year of manufacture. Recognize the critical components of your machine that may require replacement parts due to wear and tear or regular maintenance. The owner’s manual or technical documentation for your machine is a goldmine of information. It provides detailed specifications, part numbers, and maintenance guidelines. Always refer to the manual when sourcing gear parts to ensure compatibility and proper fit.

Ensure Parts Authenticity

Counterfeit gear parts can lead to machine malfunctions, breakdowns, and safety hazards. Always verify the authenticity of parts, especially when dealing with unfamiliar suppliers or meager prices. Look for certification marks, holograms, and labels that indicate the part’s authenticity. When purchasing gear parts, ask for documentation such as certificates of authenticity, warranties, and test reports. Legitimate suppliers will readily provide these documents. Maintain detailed records of your purchases and the parts installed in your machines. This documentation is invaluable for warranty claims and maintenance.

Consider OEM and Aftermarket Gear Parts

OEM gear parts are produced by the same manufacturer that built your machine. These parts are known for their quality and compatibility. While OEM parts may come at a premium price, they offer the assurance of precise fit and optimal performance. Third-party companies manufacture aftermarket gear parts and are typically more affordable than OEM counterparts. They can be a cost-effective option for routine maintenance and non-critical components. When considering aftermarket parts, research the manufacturer’s reputation and verify compatibility with your machine.

Harness the Power of Online Resources

Online marketplaces like eBay and Amazon offer a vast selection of gear parts. These platforms allow you to compare prices, read reviews, and access a global suppliers marketplace. However, exercise caution and thoroughly research sellers to ensure reliability and authenticity. Many machine manufacturers maintain official websites with online parts catalogs and ordering systems. These websites provide a direct source for OEM gear parts. Explore the manufacturer’s website for part compatibility information and technical specifications.

Implement Preventive Maintenance

Implementing preventive maintenance programs can significantly reduce the need for emergency gear part replacements. Regular inspections and servicing can identify issues before they become critical. Keep detailed records of maintenance activities, including the parts replaced and their condition. Building a stock of essential spare gear parts for your machines is a proactive approach to minimizing downtime. Consider keeping spare parts for critical components and those prone to wear and tear. Regularly review your inventory to ensure that parts are in good condition and up-to-date.

As a machine maven, securing top-notch gear parts is essential to ensure your machines’ continued efficiency and reliability. You can effectively source the components you need by understanding your machine’s specifications, forging relationships with reputable suppliers, verifying parts authenticity, and considering the benefits of both OEM and aftermarket gear parts. Embracing online resources expands your options and streamlines the parts-sourcing process. Additionally, implementing preventive maintenance and maintaining a spare parts inventory minimizes downtime and keeps your machines at their best. With these six essential tricks, you’ll be well-equipped to keep your machines in peak condition and maintain the smooth operation of your industrial processes.

Discover more from Futurist Architecture

Subscribe to get the latest posts sent to your email.