In recent years, the architecture industry has seen many changes and developments that continue to shape it to this day. Laser cutting is one of these revolutionary processes.

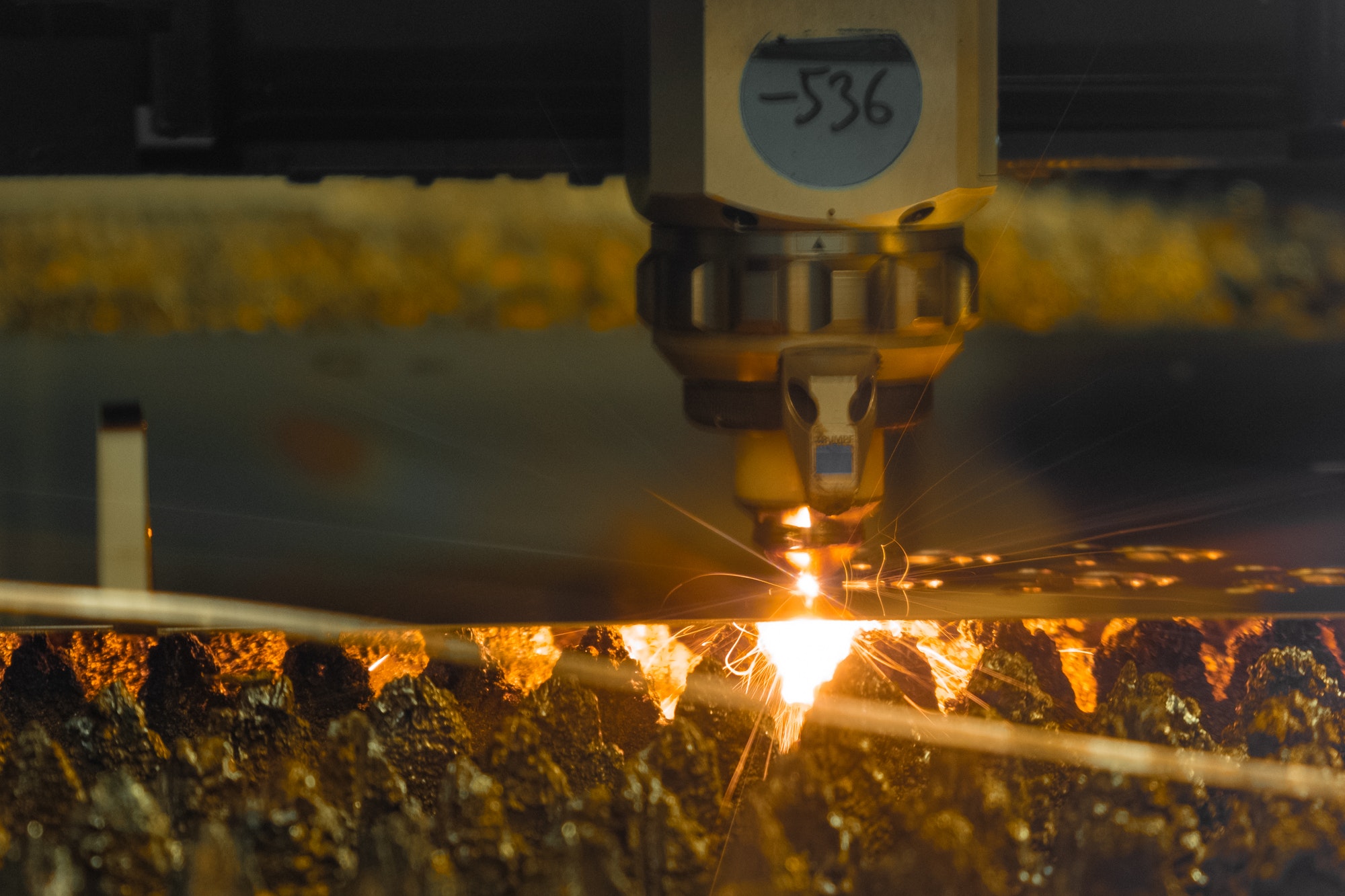

Conventional tools such as drills and saws are still used to turn the plans drawn by architects into actual buildings. They’re used to make holes and cut tubes, beams, and section bars, among others. However, they can’t be cannot be used to create contours or slotted holes and must be changed for each hole size – an issue that’s non-existent with laser cutting. In a nutshell, laser technology overcomes many limitations that conventional tools face and makes it possible to cut holes and complicated contours at high speed with immense precision.

If you’re thinking about using CNC laser cutting services for your own projects or want to learn more about the possible future of this cutting-edge technology, continue reading the article below.

Laser Cutting in Architecture and Construction

It’s no secret that the design of steel elements must take structural feasibility into account and add factors such as construction time and overall cost to the already complex equation. Over the past years, we’ve witnessed a steady transition from mainly using reinforced concrete to the widespread use of steel. This step marked the architecture’s shift toward greater freedom of styles and shapes that made it possible to construct landmarks such as Burj Khalifa in Dubai or Taipei 101 Tower in Taiwan.

Building with steel allows the architects to design buildings with a light structure and makes it easier to increase resistance in response to changes resulting from natural events, such as earthquakes or hurricanes. Moreover, man-made disasters, like the September 11 attacks, led to a greater understanding of “progressive collapse,” when a succession of structures falls like a stack of cards, just like the WTC towers did.

Lessons learned from these events led to changes in the usage of steel and technologies such as laser cutting in the construction industry and allowed to limit the widespread use of reinforced concrete. Furthermore, building with steel allows for faster construction times.

Steel constructions use components produced in the factory with machine tools that can produce parts ready for assembly on-site. Laser cutting technology allows cutting parts such as large-diameter tubes, which are strategic for high-precision constructions designed with modernity in mind. It also improves the mechanical performance of vital elements such as joints, and due to how precisely they’re cut, it reduces and simplifies the installation time. Thanks to laser cutting technology, we’ll see even more incredibly high-rise buildings designed by skilled and innovative architects.

Benefits of Laser Cutting Technology

Laser cutting has huge advantages over traditional metal cutting methods, providing the precision and power that help produce better results on an unprecedented scale. Here’s more about the main benefits of this technology:

Shorter Time and Lower Costs

As our world goes through the fourth industrial revolution, architects and construction companies often need to make well-calculated decisions to remain competitive in the busy landscape saturated with new developments. Laser cutting is a perfect solution for lowering production costs, improving its speed, and keeping productivity up. Additionally, it also allows increasing operational control. Companies that require a high volume of parts for large-scale projects with a higher level of intricacy can use laser cutting to increase their capabilities.

Using Many Different Materials

Thanks to the advancements that laser cutting technology provides, architects and construction companies can now experiment with materials aside from steel, such as aluminum, brass, or copper. Depending on the given project’s needs, lasers can cut anything from the most complex to really simple parts in small or large batches. Lasers can also handle materials of varying thicknesses, from 0.5mm to 30mm.

Pre-Fabricating Future Builds

Pre-fabricated construction is an innovative practice that’s already becoming increasingly popular and will only continue to do so in the next few years. It involves preparing various precisely-cut components that then can be quickly and relatively effortlessly put together using tab and slot techniques. The parts are practically ready-to-build. What is more, pre-fabrication allows taking much of the work away from the construction site, making the whole process much faster.

Greener Solutions

These days, people are becoming more and more aware of all the environmental concerns our world faces. With these in mind, many companies set targets such as carbon reduction and improving sustainability. Laser cutting can provide an energy-efficient solution for companies in the construction industry, and the architects design the new developments. Not only does this technology cut down the carbon footprint, but it also reduces metal waste. Additionally, materials such as steel, which is the main focus of laser cutting, can be recycled over and over without loss of quality.

In Conclusion

To sum up, the vast capabilities of modern laser cutting technologies will take the construction industry to new heights and are set to play a huge part in revolutionizing the way vital infrastructure such as bridges, apartment complexes, and public buildings are built. A lot has changed in the past decades, with architects and engineers drawing many conclusions from historic events and experiences of their predecessors.

Laser cutting technology also comes with its own set of advantages, including the fact that it can shorten the time of production of different parts, lower their costs, and use materials different than just steel. It’s also a more environmentally friendly solution for the construction industry.

Discover more from Futurist Architecture

Subscribe to get the latest posts sent to your email.

![modern apartment [article_title]](https://www.futuristarchitecture.com/wp-content/uploads/2025/03/5-Cosmic-Hacks-to-Starfield-Your-Ceiling-With-Recessed-Lighting-900x600.jpg)